Machinery, Heavy Items

Machinery, Heavy Items

In industries that handle heavy machinery and large items, the importance of reliable, durable strapping solutions cannot be overstated. Composite strapping is an advanced packaging material designed to enhance the safety and security of heavy loads during transport and storage. Combining the strength of polypropylene with the resilience of polyester, composite strapping offers superior performance, making it the go-to choice for businesses dealing with machinery and heavy items.

What is Composite Strapping?

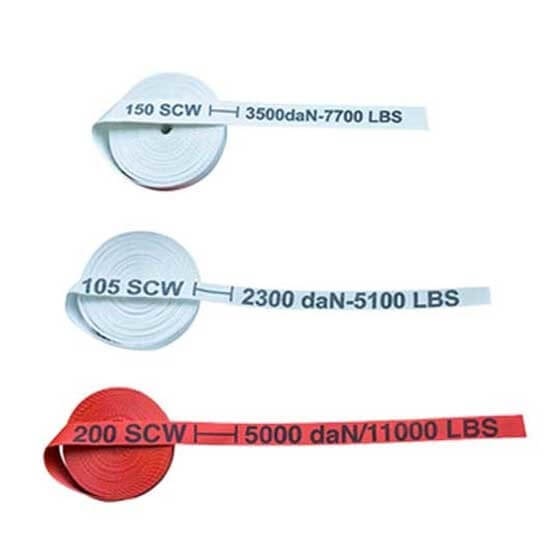

Composite strapping is a synthetic strap that combines the best properties of various materials to create a product that is both strong and flexible. Typically made from a composite of polypropylene and polyester filaments, this strapping is resistant to abrasion, UV light, and moisture. It is specifically engineered to provide maximum holding power and excellent shock absorption, ensuring that your heavy items are securely packaged during transit.

Key Benefits of Composite Strapping in the Machinery Sector

- High Strength-to-Weight Ratio: Composite strapping offers exceptional tensile strength while being lightweight. This makes it easy to handle and reduces the overall weight of packaged goods, which can lead to cost savings in shipping.

- Durability: Engineered to withstand the rigors of transportation, composite strapping is resistant to breakage, stretching, and UV degradation. This durability ensures your heavy machinery and equipment remain secured, even in challenging handling conditions.

- Weather Resistance: The materials used in composite strapping are designed to resist the effects of moisture and temperature fluctuations, making them ideal for outdoor storage and transportation.

- Cost-Effective: With lower replacement rates and reduced risk of damage, composite strapping can reduce long-term packaging costs and minimize losses associated with shipment damages.

- Versatility: Composite strapping is suitable for a wide range of applications, from bundling heavy machinery components to securing large pallets. It can be used in various industries, including manufacturing, construction, and logistics.

- Eco-Friendly Options: Many composite strapping products are made from recyclable materials, making them an environmentally friendly choice for companies looking to reduce their carbon footprint.

Application

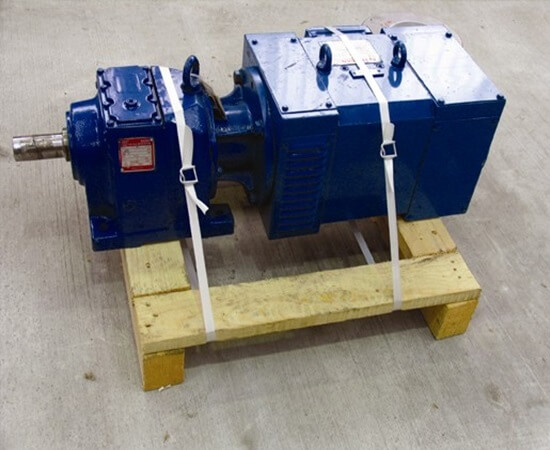

- Heavy Machinery: Used extensively in the packaging of construction equipment, agricultural machinery, and industrial tools to ensure safe transport and storage.

- Palletized Loads: Perfect for securing large pallets, minimizing the shifting of items during transit, and protecting the integrity of the load.

- Lumber and Steel: Ideal for bundling heavy steel and lumber materials, providing reliable support during storage and shipping.

Best Practices for Using Composite Strapping

- Proper Material Selection: Choose the right width and thickness of the composite strapping based on the weight and dimensions of the items being secured.

- Adequate Tensioning: Use tensioning tools to ensure the strapping is adequately tight without causing damage to the items.

- Sealing Techniques: Utilize the appropriate seals and buckles to secure the ends of the strap, providing additional strength and security.

- Regular Inspections: Check for signs of wear, abrasion, or damage in the strapping over time, especially if items are stored for extended periods or exposed to the elements.

For expert advice on industrial solutions contact us now

CONTACT FORM

Enter your details in the form and we will call you.

Our Global Quality Commitments